Digital Manufacturing

Precision Additive Manufacturing (PAM)

This is a Multi-dimensional research program with active projects on Design for PAM, process-Planning for PAM, PAM Process Control, and PAM Post-Processing

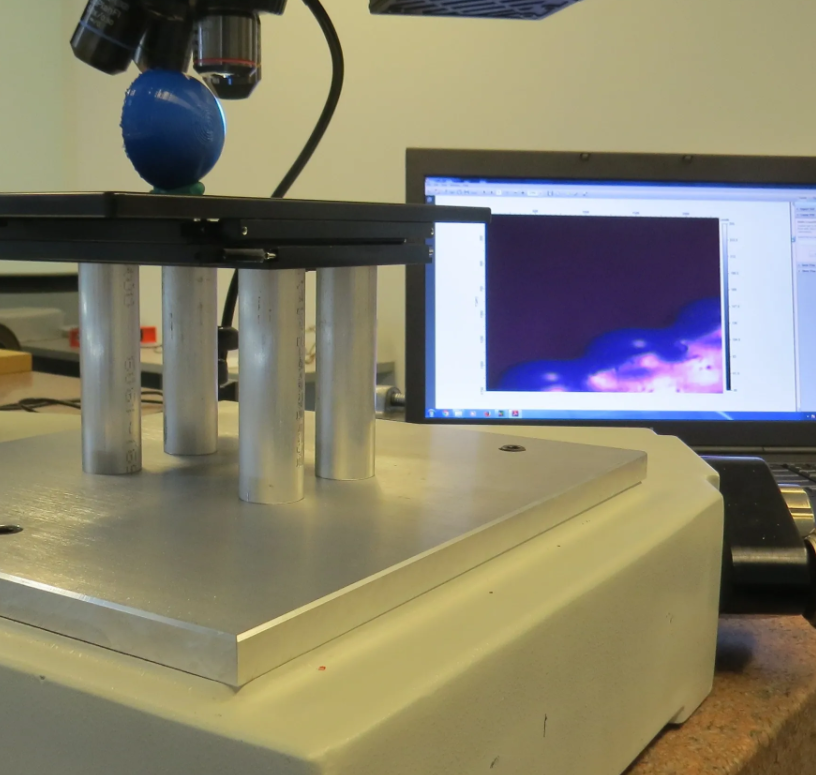

Manufacturing Error Detection

This refers to a group of projects on online detection of errors in manufacturing products and processes using the optical metrology and inspection sensors. These projects are well aligned with the objectives of Industry 4.0 using advanced levels of data analytics and artificial intelligence.

Capstone Projects

Layer-less 3D Printing Mechanism (2016-17)

This project developed and built a layer-less 3D printing solution to improve and extend the capabilities of an existing system. Layer-less 3d printing, also known as CLIP, continuous liquid interface production, is a method of additive manufacturing that implements photo polymerization that creates smooth-sided solid objects of a variety of shapes. This process starts with a pool of liquid resin and the bottom of the pool is to be transparent to ultraviolet light. The UV light shines through the transparent bottom which then illuminates the cross-section of the object. The UV light then solidifies the resin. The object then slowly rises which allows the resin to flow underneath the object and continue to contact the bottom of the object. Below the resin lies an oxygen-permeable membrane which prevents the resin from sticking to the bottom of the pool

Members: Dylan Bender, Abishek Kailash, Smitkumar Patel, Saif Hussaini, Daniel Santram, Minesh Patel

3D Printed Vacuum Layer Gripping System (2017-18)

The objective of this project was to design a fully controllable vacuum gripping system using 3D printed Nylon. The tool spans 40” x 48” to allow the palletizing of full North American pallet layers. The gripping system required controllable sections to provide flexible and efficient palletizing solutions. In addition, the overall assembly weight must be 50% of the benchmark competitor tool, while maintaining the same payload capabilities of 250 kg. The use of engineering tools such as CAD, FEA, CFD, and Topology Optimization accommodate the most efficient use of the SLS technology.

Members: Enoch Chan, Maher Mikhail, Nirmal Weerasinghe, Spencer Wu

Design and Development of a Green Part 3D Printer (2019-20)

The project scope was to create a slide 3D printer with the ability to be mass produced into the market that is safe to use but also can create a green part. A Green part as described previously is a 3D printed component which is produced from metal powder and a polymer binder which undergoes processes to be extruded into a green part. The green part goes through debinding processes to come a brown part. The result after debinding is a brown part which undergoes sintering to create a strong bond between the metallic particles to produce a metal 3D printed component.

Members: Judy Afana, Frank Du, Temi Oduyale, Alex Goncalves, Remon Armanious, Evan Murphy-Snow, Omar Awaddeh, Mohammed Baabbad

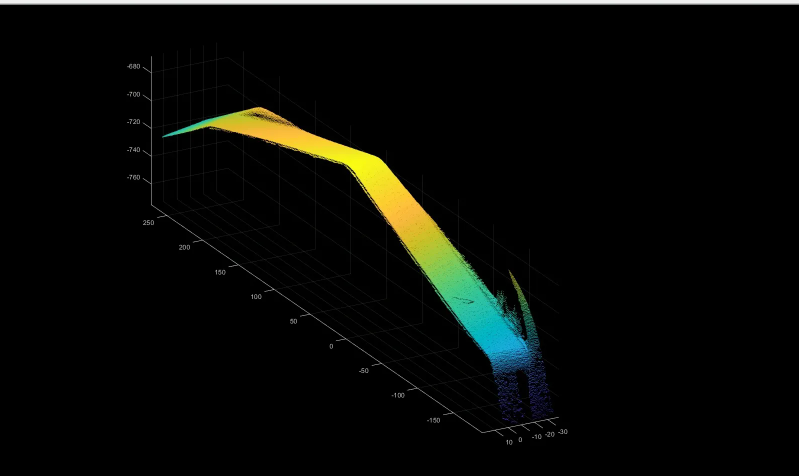

Drone-Based System for 3D scanner for Mechanical Systems and components (2020-21)

The purpose of this capstone was to design a position tracking drone-based system for 3D modeling using photogrammetry. It was important to develop a code to allow the drone to accurately locate important features from images and transform them into 3D points. Photogrammetry is the method of mapping an area and recreating it in a 3D rendering. This process includes but is not limited to, pulling points, matching them together, and then accounting for pose estimation. Using key features such as position tracking, these drones can reconstruct areas where GPS navigation is unavailable or inaccurate.

Members: Kajapirian Arulrasa, Peter Lysyk, Mitchell Maguire, James Nowicki, Karolina Piskorski

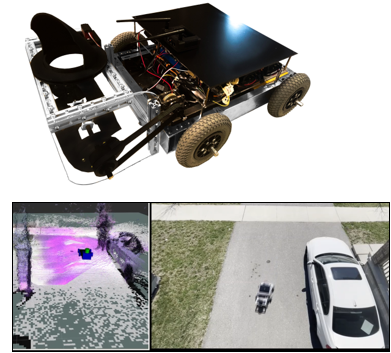

IOT-based Autonomous Snow Removal (2020-21)

This Capstone project is the “Internet of Things” (IoT for short) based Autonomous Snow Removal Robot. The purpose of this project was to develop a snow removal mechanism that is capable of clearing home driveways autonomously through receiving IoT-based weather notifications product will have the ability to determine the appropriate time to plow snow and ensure it does not bring harm to objects or humans whilst completing its task. This includes autonomous navigation for path mapping, IoT cloud computing for device enablement, snow removal mechanism, and drive system to traverse snowy conditions.

Members: Harvin Kaura, Jonathan Selvanathan, Tristan Zonta, Kieran Wilson, Jay Patel

Autonomous Indoor Cleaning Robot (2020-21)

Due to the ongoing danger of the global pandemic, there has been a major need or new disinfection technologies to help combat the spread of COVID-19, the main aim of this project was to create an autonomous indoor cleaning robot capable of combating the spread of COVID-19 in places such as stores, offices, and hospitals. The autonomous robot was tasked to be completely wireless and could disinfect the air with the use of a HEPA filter and UV-C light. It will have the ability to create 3D maps of its surroundings with the use of an intel realsense L515 camera as well as navigate through various parts of the building using its generated map.

Members: Mehul Rana, Jai Patel, Mohet Narang, Steve D’souza, Princewill Onyechie